Lead-free Ammo: Everything You Need to Know

Why has lead been the standard for firearm ammo for such a long time? To put it simply, lead is readily available, very dense, and easy to form. But in recent years, bullets made from lead have become controversial. Because lead is a toxic substance when ingested by humans and animals, some ammunition manufacturers have started using alternative metals instead. Thus, a new type of bullet technology has been born: lead-free ammunition.

Buy your lead-free ammo in several calibers from Pro Armory.

What is Lead-Free Ammunition?

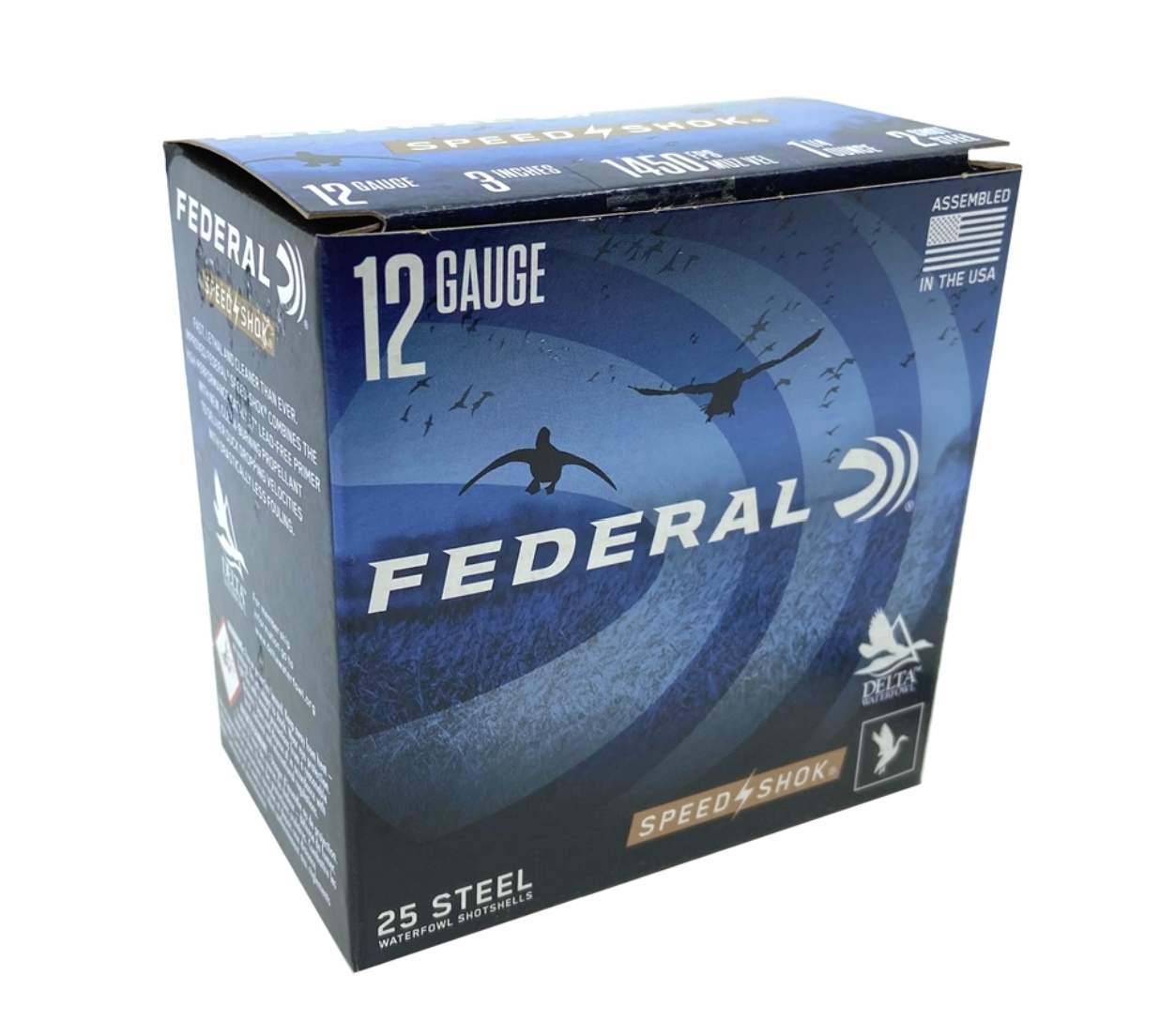

As the name implies, lead-free ammunition is any type of handgun, rifle, or shotgun ammunition that fires shot or bullets made from a metal other than lead. For instance, lead-free handgun and rifle bullets are made from solid copper. But lead-free shotgun pellets (a.k.a. shot) are made from either bismuth or steel. While these alternative metals aren’t as toxic as lead, they also come with their own disadvantages.

For example, steel is only 69 percent as dense as lead. Copper is only 79 percent as dense, and bismuth is only 86 percent as dense. In addition, all three metals are significantly less malleable (easily formed) than lead. That lack of density and malleability means that projectiles made from these metals have significantly less inertia than lead projectiles, meaning they don’t penetrate as deeply or deform as easily.

This is why lead shot and lead bullets with copper jackets have remained the standard in ammunition today.

The Lead-Core vs. Lead-Free Ammunition Controversy

Since its invention by Swiss Colonel Eduard Rubin in 1882, the copper jacketed lead core bullet has represented the pinnacle of bullet technology for shooters and hunters alike.

However, in recent years, there has been considerable controversy around the use of ammunition that fires pure lead, lead alloy, or lead-core bullets. Biologists suggest that projectiles containing lead cause poisoning in both humans and animals.

Autopsies done on the carcasses of dead raptors, scavengers, and waterfowl clearly show that several of them die due to elevated levels of lead in their bloodstream. Biologists attribute these deaths to the ingestion of lead shotgun pellets or lead fragments from jacketed lead-core bullets.

But how exactly does lead enter the bloodstream of these birds? In the case of migratory game birds, such as mourning doves and waterfowl, these bird species have a muscular internal organ called a “gizzard” that grinds their food prior to digestion. They do this by eating tiny pebbles or pieces of gravel — and sometimes lead shotgun pellets. In the case of raptors (such as eagles and hawks) or scavengers like turkey vultures and California condors, they can ingest lead by feeding on game that was wounded but not recovered by hunters. Otherwise, they may feed on gut piles (containing lead fragments) left by hunters who field dress their game.

While there is still more to discover about its effects, many biologists and conservationists have campaigned to ban the use of lead or jacketed lead-core ammo for hunting any species of animal.

Why Hunters Should Use Lead-Free Ammunition

While using traditional lead ammo is mostly about personal preference, there are several reasons hunters might use lead-free ammo:

- Legal Hunting Regulations - U.S. federal regulations require hunters to only use lead-free shotgun ammunition when hunting waterfowl. Plus, some U.S. states require that hunters only use lead-free ammunition when hunting medium and large game species (such as deer, elk, moose, and bears).

- Prevent Animal Lead Poisoning - Lead-free ammo prevents waterfowl, raptors, and scavengers from ingesting lead shot or lead fragments. This makes for more available wildlife on your next hunting trip and prevents the unnecessary death of animals due to a toxic environment.

- Cleaner Meat - Despite what recent studies have shown, the fact is that lead-core jacketed bullets fired at very high speeds from modern hunting rifles do fragment when impacting game animals. These lead fragments contaminate the meat to some degree. When hunting with lead ammo, hunters are either forced to cut away portions of the meat that may be contaminated or risk consuming the lead fragments when they eat the meat. Lead-free ammunition prevents this problem and provides peace of mind for many hunters.

See Why So Many Customers Love Pro Armory

For our team, providing great ammo, tactical gear, and world-class training to the great American shooter is just one more way to serve & celebrate our great country. We're committed to giving you everything you need to accomplish your shooting goals -- all at an affordable price. Join the thousands of satisfied customers that love shopping at Pro Armory.

Your veteran customer service guys are kicka$$!! I won’t order anywhere else now! – TY

Spoke with one of your vets Gabe on the phone. So nice to be able to speak with a former vet – U guys are awesome! Kudos to you for hiring veterans! - LT

Great prices, fast shipments!! Always come on or before the date on the statement. If you see an item at Sale Prices buy it fast, because it won’t last! – BW

Get All Your Lead-Free Ammo From Pro Armory

When you order from Pro Armory, you’re ordering from a team of veterans dedicated to giving you the best online ammo shopping experience. Our goal is to provide you with the top ammunition products from name brand manufacturers at the best possible price. All the products listed on our site are in stock and ready to ship as soon as you place your order

If you are a hunter or shooter looking for lead-free ammunition, Pro Armory is the place for you! With a wide selection of lead-free shotgun, handgun, and rifle ammunition to choose from, Pro Armory has the brands, calibers, and cartridges to meet your needs.

Deep Dive: Lead-Core vs. Lead-Free Bullets

Other than the presence of lead, what makes lead-core handgun/rifle ammo different from lead-free handgun/rifle ammo?

The short answer: the projectiles they are loaded with.

Lead-core ammunition is loaded with copper jacketed bullets containing soft lead cores. Lead-free ammunition is loaded with solid copper bullets. In essence, lead-free bullets are made from a different material and require a different manufacturing process than jacketed lead-core bullets

Let’s take a closer look at each of these different bullet designs.

Lead-Core Bullets

Copper jacketed lead-core bullets are made from a combination of copper and lead, which creates a bullet with a soft center and a hard outer shell. By varying the amount of lead exposed at the tip of the bullet and the thickness of the copper jacket’s walls, bullet manufacturers can design both rifle and handgun bullets that expand on contact in a controlled manner at different velocities.

Copper jacketed lead-core bullets are made using multiple different methods:

Manufacturing Method 1: Cup-and-Draw

When using the cup-and-draw method, a series of round discs are punched out of a narrow strip of copper. Each copper disc is then pressed by a series of dies. This first forms them into short, thick cups, then gradually elongates each cup until it reaches the desired length and wall thickness. From there, a lead cylinder is inserted into the elongated copper cup and both materials are forced into a series of dies. This forces the copper jacket to close over the lead core and traps it inside to take on the shape of the finished bullet.

Manufacturing Method 2: Extrusion

With the extrusion method, the hollow copper jackets are formed from solid copper slugs rather than copper discs. First, long coils of thick copper wire are cut into short cylinders. Each cylinder is then pressed by a series of dies, which forms them into short, thick, cups like the discs in the cup-and-draw method. From there, the process is the same in that the cups are pressed and elongated to the desired length and wall thickness before receiving a lead cylinder. Then, the two materials are forced into a series of dies to form the final bullet shape.

However, forming bullets in this way doesn’t cause the lead core and the copper jacket to adhere. This type of bullet is known as a non-bonded core bullet, or a “cold core” bullet. The lack of a bond between the jacket and the core can cause the two components to separate upon impact (and not penetrate as deeply).

Other Manufacturing Methods

To prevent this, bullet manufacturers use different methods of bonding the jacket to the core. For instance, some manufacturers may form one or more ribs or partial partitions inside the hollow jacket before inserting the lead core. This ensures the lead is gripped by the protrusions when the bullet is formed. Another method is to pour molten lead into the hollow jacket and allow it to cool and solidify before forming the jacket, bonding the core to the inside of the jacket. This type of bullet is known as a “hot core” bonded bullet.

Advantages of Lead Bullets

Because lead is a softer metal than copper, a copper-jacketed bullet with an exposed lead tip will expand rapidly upon impact with a soft target (such as a game animal). The pressure generated by the impact will compress the lead core inside of the copper jacket, causing the jacket to rupture and expand the diameter of the bullet. With these techniques, manufacturers can produce bullets that expand rapidly at low velocities (for use with handguns) while also producing bullets that expand slowly at high velocities (for use with rifles).

Lead-Free Bullets

Lead-free bullets are made from solid copper alloy (rather than a hollow copper jacket with a soft lead core). They require entirely different methods of manufacturing that are both more complicated and more expensive than traditional lead-core bullets.

Manufacturing Method 1: Extrusion

To make extruded copper bullets, long coils of thick copper alloy wire are cut into short cylinders called “slugs.” Each slug is pressed by a series of dies, which eventually force it to take on the shape of the finished bullet. While this method of forming copper bullets might seem simpler than the methods used for lead ammo, it’s actually more complicated. It requires far more dyes and additional pressing sequences to form the finished bullets.

Manufacturing Method 2: Lathe Turning

Solid copper alloy bullets can be turned on a computer-controlled lathe during production, which is simpler than forming them by using dies. However, it’s also less efficient because the bullets are formed by removing metal rather than pressing slugs. Because of this, turning copper bullets on a lathe produces more waste than pressing them.

Advantages of Lead-Free Bullets

Solid copper bullets work a bit differently than copper jacketed lead-core bullets. Without the lead core, solid copper bullets lack an exposed lead tip. This means they don’t have the internal pressure created by the lead tip and core when they impact a soft target (decreasing the expansion). In order to make solid copper bullets expand on impact, bullet manufacturers rely on either a hollow point or ballistic tip.

Due to their construction, solid copper bullets often expand in a far more controlled manner than jacketed lead-core bullets with wider expanded diameters. Beyond that, they often retain significantly more weight and thus penetrate deeper than even bonded core bullets.

Solid copper bullets can also be designed to fragment (rather than expand) upon impact. This is called a “frangible” bullet. This type of bullet is useful in situations where over-penetration of the target might present a danger to other animals or humans (because it breaks up into several small fragments after impact). Because each of these fragments have significantly less mass and inertia than the original bullet, the fragments won’t penetrate as deeply. This also makes them ideal for home defense, where you don’t want the bullet to penetrate through the target and accidentally hit a loved one.

On the other hand, when hunting dangerous game animals such as grizzly bears, rhinoceros, or Cape buffalo, hunters sometimes want a bullet designed for as much penetration as possible. These hunters may use a type of lead-free bullet called a “monolithic solid.” This type of bullet is made from a single piece of copper and features either a round nose or a flat nose with no hollow points or ballistic tips. This enables the bullet to have as much weight as possible with no expansion. Thus, this type of copper bullet will produce a very deep and straight wound channel that can easily punch through bone.

Even though copper jacketed lead-core bullets remain the gold standard for most shooters today, solid copper bullets generally perform just as well. But unlike lead-core bullets, there’s no environmental hazard.

Lead or Lead-Free: Which is Best?

Due to recent studies surrounding lead-free ammunition, hunters are slowly coming to accept it as a viable alternative to jacketed lead-core ammunition. Its performance is equal to that of lead-core ammunition, and even surpasses it in some cases.

Today, ammunition manufacturers are starting to offer lead-free ammo in a wider variety of calibers, cartridges, and bullet weights. In a few years, the popularity of lead-free ammunition may eventually surpass that of lead-core ammunition, as hunters become aware of the potential health hazards and known environmental hazards of using lead ammo.

However, the fact remains that traditional lead ammunition is much cheaper than lead-free ammunition. Because of this, they both present advantages to shooters with different goals. As long as you follow the law, the decision is up to you.

Frequently Asked Questions

Lead-free ammunition is any shotgun, handgun, or rifle ammunition that fires shot or bullets made from metals other than lead. This includes copper, steel, or bismuth.

Yes. Although both lead-core and lead-free bullets tend to be unreliable at handgun velocities, solid copper controlled expansion bullets do expand reliably at rifle velocities and retain significantly more of their weight than lead-core bullets. So even though lead-free bullets are often 15 to 20 grains lighter than jacketed lead-core bullets, they tend to have reliably wider expansion with greater penetration.

Using lead-free ammunition prevents lead poisoning in animals and keeps the environment cleaner from toxic materials. When hunting migratory waterfowl, U.S. federal hunting regulations require that all hunters use only lead-free shot. Otherwise, some U.S. states require hunters to use lead-free ammunition when hunting medium to large game species.

The grooves that are pressed or milled into the base of solid copper bullets are designed to reduce the surface area of the bullet. This reduces the amount of friction between the bullet and the inside of a gun barrel, increasing muzzle velocity while also reducing copper fouling in the barrel’s grooves.

Lead-free bullets are made of solid copper, which is much more expensive and difficult to shape than pure lead or lead alloy.

Get Top Quality Lead-Free Ammo from Pro Armory

Whether you use traditional lead or lead-free ammunition, Pro Armory has you covered. While we carry a ton of lead-core ammunition, we also have a great selection of lead-free products for hunters who prefer to use them. We carry some of the most popular lead-free hunting cartridges, such as .308 Winchester, .30-30, and 7mm Remington Magnum. We also carry steel shot shotgun shells for waterfowl hunters.

Buy your ammo from a company that gives a sh*t about you — and the environment. Get lead-free ammo in the caliber you need today for your next hunting or plinking excursion.

Buy Lead-Free Ammo Today