Quick-Answer

Brass usually seals the chamber better, runs cleaner, and is reloadable. It’s great for AR-15s and precision work. Steel is cheaper and often robust in harder-extracting platforms (many AK/FAL-style rifles), but it can run dirtier and may stick without proper coatings. For defense/competition, favor quality brass. For budget practice, vetted steel from reputable makers can work.

Caution: Always check your firearm manufacturer’s recommendations and warranty terms before using alternate-case ammo (steel or foreign surplus). For defense and duty use, prefer proven loads; for practice, validate function and clean more frequently.

Key Takeaways

- Brass expands better, reduces fouling, boosts reliability.

- Steel saves money; coatings affect extraction.

- Reloading favors brass; steel is limited.

- Platform matters: ARs like brass, AKs tolerate steel.

- Accuracy varies by load quality, not just case.

- Always validate with a 200–500 rds (paced + rapid) or 3×50 staged; check extraction often and follow safety rules.

A professional carbine instructor recounts two range days: a soft-shooting AR-15 choking on bargain steel during a muddy drill, then an old AK running lacquer-coated steel flawlessly through a high-tempo course. Same range, different rifles—ammo case material wasn't the only variable; extraction timing and coatings told the real story.

What's the Real Difference Between Steel and Brass Cases?

The job of a cartridge case seems simple: hold the bullet, powder, and primer together. But it does much more. A case must contain explosive pressure, seal the chamber to prevent gas leakage, and facilitate smooth extraction after firing.

Brass and steel differ primarily in ductility and hardness. Brass is softer and more malleable, which generally allows it to expand under pressure and conform to chamber walls (helping form a gas seal) and then spring back slightly to ease extraction. Steel is harder and less malleable, so it typically does not conform to chambers as readily; coatings and chamber tolerances therefore matter more when running steel-cased ammo.

Experts note that the slight differences in case expansion and friction can affect how long the case stays sealed against the chamber during unlocking — a factor that can influence fouling, extraction timing, and perceived reliability.

The seal quality affects how much unburned powder and gas blows back into your gun's action. This is a crucial factor in both cleanliness and function.

Brass Ammo

Brass ammo has earned its reputation as the gold standard for several good reasons.

First, brass creates that superior chamber seal we mentioned. This means less gas and unburned powder sneaking backward into your gun with each shot. The result is a cleaner-running firearm with fewer carbon deposits that could cause malfunctions.

Second, brass cases can be reloaded multiple times. The material allows for reliable resizing to the original dimension. It gives handloaders the ability to craft custom loads and save money over time. For folks who shoot a lot, this becomes a major advantage. You can reload brass cases 5-10 times or more with proper care. Brass can typically be reloaded multiple times (often several cycles) depending on case quality, caliber, chamber dimensions, and how aggressively the cases are worked and annealed. Expect reuse counts to vary widely.

Third, brass-cased ammunition tends to run more smoothly in firearms with "softer" extraction cycles, such as the AR-15 platform. These guns typically have straight-walled cartridges that extract with lighter pressure. It’s a perfect match for brass's physical properties.

In a few high-stress extraction systems or very aggressive extractors (some older surplus rifles), a softer rim can deform if the extractor and chamber timing are unusually violent. This is uncommon in modern production rifles, but it illustrates why you should test any new ammo in your specific firearm.

But brass isn't perfect for every situation. In some older surplus rifles with aggressive extractors—particularly certain FALs and AK-pattern guns—brass can actually tear at the rim. The softer metal might not stand up to the violent extraction these platforms sometimes employ.

Magtech 5.56 NATO 62gr FMJ

$26.54

at Pro Armory

Prices accurate at time of writing

Steel-Cased Ammo

The biggest selling point of steel-cased ammunition is price. It's significantly cheaper than brass. For casual range sessions and high-volume practice, this cost advantage can mean the difference between shooting 200 rounds or 500 rounds on the same budget.

Steel cases offer surprising durability in certain platforms. According to firearms experts, "A tapered case fares much better during extraction, since once the seal is broken and the case moves even the slightest amount to the rear, friction between the case and the chamber is appreciably attenuated." This explains why certain cartridges like 7.62x39mm run so well in AK platforms even with steel cases.

A common myth suggests steel ammo is inherently lower quality than brass. The truth? Material alone doesn't determine quality—manufacturing standards do. Some manufacturers have produced steel-cased lines held to tighter tolerances (occasionally marketed for higher accuracy), showing that manufacturing quality and consistency — not case material alone — determine accuracy potential. High-quality steel-cased loads from reputable factories and modern manufacturing controls can perform reliably and even with good accuracy in many platforms.

Important: Some surplus or low-cost steel-cased ammunition uses corrosive primers (salts that attract moisture and cause rust). Corrosive primers require immediate, proper cleaning with water-based steps per manufacturer guidance. If you see a round labeled “corrosive” or suspect surplus steel, treat it accordingly—do not assume modern steel-cased = non-corrosive.

Steel cases do face two legitimate challenges: they may expand unevenly in some chambers (leading to stuck cases), and they cannot be safely reloaded multiple times. Once expanded, steel tends to stay that way. Experts note that slight differences in case expansion and friction can affect how long the case stays sealed against the chamber during unlocking—a factor that can influence fouling, extraction timing, and perceived reliability.

STERLING SC 762X39 123GR FMJ 20 per box

$12.47

at Pro Armory

Prices accurate at time of writing

Extraction & Cycling

Your gun's operating system plays a huge role in how well it handles different case materials. This explains why platform-specific ammo preferences exist.

AR-15s and similar Western designs typically employ a more gentle, longer extraction cycle. These guns were designed around brass-cased ammunition, with extractors that apply moderate force over a longer distance. When fed steel cases, some ARs may struggle with inconsistent extraction or experience more wear.

AK-pattern rifles, FALs, and many Eastern Bloc designs use a shorter, more forceful extraction cycle. As Wikipedia notes, "This is less of a problem for small arms of the former Warsaw Pact nations, which were designed with much looser chamber tolerances than NATO weapons." These guns yank the case out with authority - sometimes too much authority for softer brass.

Interestingly, cartridge shape also matters. Tapered cases like 7.62x39mm extract more easily regardless of case material because the taper reduces friction once extraction begins. Straight-walled cases need more help from proper case material and expansion characteristics.

Gas system tuning (adjustable gas blocks, heavier/lighter buffers, spring swaps) can sometimes improve function with different case types, but changes should be made carefully. Improper tuning can increase wear or reduce reliability; make one change at a time and validate with function testing under representative conditions.

Case Coatings: Polymer vs. Lacquer

Steel cases need special coatings for two reasons: to prevent corrosion and to improve case feeding and extraction. Without these coatings, steel cases would rust and might stick in chambers due to their rough texture compared to naturally slick brass.

Two main coating types dominate the market: polymer and lacquer. Polymer coatings, found on brands like Wolf, are more modern. Lacquer coatings, common on Brown Bear ammo, are older technology but still widely used.

A persistent myth claims that lacquer melts in hot chambers. It creates extraction problems and gumming up guns. However, extensive testing by Lucky Gunner found lacquer-coated Brown Bear ammo actually malfunctioned about half as often as polymer-coated Wolf ammunition in AR-15 platforms—directly contradicting the common belief.

What matters more than coating type is how you maintain your firearm. Any steel-cased ammunition will leave more residue in the chamber than brass. Regular cleaning, especially of the chamber and extractor, becomes essential for trouble-free operation.

Accuracy & Consistency

Does case material affect accuracy? Yes and no. But manufacturing standards matter more.

The case material itself has minimal direct impact on accuracy. What really counts is the consistency of the powder charge, bullet seating depth, primer pocket dimensions, and overall quality control during production. A premium steel-cased round can easily outshoot budget brass ammunition.

Hornady proved this point with their Steel Match line, which delivers competition-worthy accuracy despite using steel cases. The difference? Tight quality control throughout the manufacturing process.

For most recreational shooters, the accuracy difference between quality brass and quality steel ammunition falls within acceptable limits. At typical self-defense or plinking distances (25 yards or less), you likely won't notice any significant difference.

Precision shooters pushing the limits at longer ranges may prefer brass for its more consistent internal volume and pressure curves. But for everyone else? The person behind the trigger matters far more than the case material in front of them.

Reloading Reality Check

Reloading dramatically changes the brass vs. steel equation for many shooters. Here's why:

Brass cases can be reloaded multiple times. Anywhere from 5-10 loadings for typical range ammunition, and sometimes more with careful preparation. This means your initial investment in brass-cased ammo can pay dividends as you reuse those cases again and again.

As the American Hunter explains, "If you are a reloader, don't bother with the steel cases. It's more trouble than it's worth. Although it is possible, especially with boxer-primed cases." Steel simply doesn't take to the reloading process well.

Reloading brass requires some equipment investment upfront: a press, dies, primers, powder, and bullets. But the per-round cost drops dramatically once you're set up. Often to less than half the price of factory ammunition.

For high-volume shooters putting thousands of rounds downrange yearly, this math becomes compelling. A $200 investment in reloading equipment might pay for itself within 1,000 rounds when reusing brass cases.

Cost, Reliability, and Use-Case Matrix

| Use-case | Priority | Recommended Case Type | Notes |

|---|---|---|---|

| Self-Defense | Reliability | Premium Brass | Chamber sealing critical; function trumps cost |

| Competition | Accuracy & Function | Match-Grade Brass | Consistency essential; reloading common |

| Precision Training | Accuracy | Match-Grade Brass | Need consistent point of impact |

| High-Volume Practice | Cost Efficiency | Tested Steel | Validate function with 500-round test first |

| AK / Surplus Rifle Range | Cost & Function | Steel with Coating | Functions well in these platforms |

Note: some firearm warranties exclude damage from certain ammunition types (including some steel-cased or non-recommended surplus). Confirm manufacturer guidance before making high-volume steel your primary practice round.

Suggested test checklist:

- Clean the gun and start fresh.

- Run 50–200 rounds at moderate pace; note failures and ejection patterns.

- Clean and inspect chambers/extractors.

- Run rapid fire strings to heat the barrel (simulate stress).

- Alternate brass/steel in magazines to observe extraction differences.

- Inspect spent cases for scratches, tearing, or hard extraction marks.

- If failures occur, stop and troubleshoot (lubrication, gas tuning, extractor spring, or stop using that ammo).

Simple Rules to Choose (Decision Flow)

Picking the right ammo doesn't need to be complicated. Follow these simple guidelines:

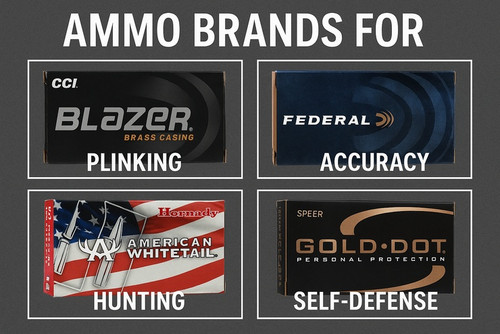

For home defense, duty use, or competition - go with quality brass ammunition. The marginal cost difference doesn't justify any potential function risk in critical situations.

For high-volume practice in modern, well-maintained guns - try steel if budget is tight, but test at least 500 rounds first to confirm function.

For AK-pattern rifles and many surplus firearms - steel often works fine and may even be preferable due to aggressive extraction.

Store steel-cased ammo in a cool, dry place and consider using desiccants or sealed containers. Check packaging for corrosion before loading, and rotate stock to avoid long-term exposure.

For reloaders - brass is the clear choice. The ability to reload multiple times offsets the higher initial cost.

Always match your ammo choice to your gun's needs, not just your budget. An AR-15 that runs poorly on steel costs you more in frustration than you save in ammo dollars.

500-Round Validation Protocol

Want to know if your gun runs well on steel? Here's how to test it properly:

Clean and lubricate your firearm according to the manufacturer's recommendations. This gives both ammo types a fair starting point.

Fire 200 rounds at a moderate pace. It allows the gun to cool slightly between magazines. Note any failures to feed, fire, or extract. Watch the ejection pattern—cases should eject consistently in the same direction.

Next, run 200 rounds through rapid-fire strings to heat up the gun. Many extraction issues only appear when chambers get hot, so this simulates demanding conditions.

For the final 100 rounds, load magazines with alternating brass and steel (if possible) to compare extraction under identical conditions.

After testing, examine your chamber and extractor for unusual wear or carbon buildup. Look at spent cases for signs of difficult extraction like scratches or deformation.

This protocol will tell you if your specific gun and ammo combination works well—more useful than general advice about what "should" work.

Maintenance & Wear

Using steel-cased ammunition requires slightly different maintenance habits.

Clean your chamber more frequently, focusing on carbon buildup that can cause extraction issues. A chamber brush becomes your best friend.

Inspect your extractor after every range session with steel ammo. It is looking for unusual wear or damage. Some guns benefit from upgraded extractor springs when running primarily steel cases.

Inspect extractors for rounded or chipped claws and check extractor spring tension periodically when using steel. Look for unusual chamber peening or scratches—steel that drags will often leave linear marks near the case head or rim. If you see such wear develop rapidly, discontinue use and consult an armorer.

Store unused steel-cased ammunition in a cool, dry place. As Wikipedia notes, "steel is more susceptible to contamination and damage so all such cases are varnished or otherwise sealed against the elements." Even with coatings, steel can corrode under poor storage conditions.

Gas system maintenance becomes more important with steel ammo, particularly in AR platforms. More carbon and residue typically means more frequent cleaning is needed.

Conclusion

The debate between brass and steel isn't as simple as "one is better" — context matters enormously. Your firearm design, intended use, budget, and maintenance habits all factor into the ideal choice.

As the National Shooting Sports Foundation recommends, always follow manufacturer guidelines for ammunition selection. Some warranties explicitly exclude damage from steel-cased ammunition, so check before you buy.

Modern coatings and manufacturing have improved steel-cased ammunition dramatically. What was once true about inconsistent steel ammo decades ago may not apply to today's offerings.

Practical summary:

- Carry / defense / competition: choose quality brass loads you have function tested in your gun.

- High-volume practice: vetted steel from reputable makers can save money — but test and clean more often.

- Reloaders: buy brass only.

- Surplus steel: verify non-corrosive primers before shooting; clean immediately if corrosive.

- Always test new ammo in your specific firearm and keep an eye on extractor/chamber wear.

Remember that case material is just one variable in ammunition performance. Bullet design, powder selection, and overall quality control often matter more than brass versus steel.

Final caution: Ammo choice is not just about price. It affects reliability, maintenance, warranty, and—most importantly—safety. Before relying on any new ammunition for critical-use roles, confirm it functions flawlessly in your firearm under realistic conditions and observe recommended maintenance intervals. When in doubt for defense or duty, choose proven brass-cased loads.

Frequently Asked Questions (FAQs)

Is steel ammo bad for my AR-15?

Not inherently, but many ARs extract brass more smoothly. Test thoroughly and clean more frequently if using steel.

Does lacquer "melt" and gum the chamber?

Not typically. Failures attributed to lacquer are usually due to carbon fouling or poor cleaning. However, lacquer can behave differently under extreme conditions; maintain the gun and check chamber residue if you experience extraction issues.

Will steel damage extractors faster?

Steel may accelerate wear in some firearms depending on extractor design and chamber tolerances; many AK-pattern rifles show negligible extra wear, while some lightly-built extractors in other platforms may show increased wear. Inspect your gun regularly.

Is brass always more accurate than steel?

No. Manufacturing quality matters more than case material. Premium steel can outshoot budget brass.

Can I use steel for home defense?

It's better to use premium brass ammunition for critical self-defense situations due to improved chamber sealing and reliability.

Why does my AK love steel but my AR doesn't?

If an AR has extraction problems with steel, test with different lots/coatings, confirm gas/timing, and consider extractor spring upgrades before abandoning steel entirely.

About the Author

Pro Armory’s writing team wrote this article. We used up-to-date research and clear sources like the Journal of Military Science, Firearms News, and the National Shooting Sports Foundation. We also checked official defense publications and guidance from the ATF, the NRA, and manufacturer manuals.

Disclaimer: This article is for education only. Always follow the maker’s directions for your firearm. Different models can handle ammo in different ways.

Pro Armory Editorial Team

Pro Armory Editorial Team